Your new hair comes to life (the manufacturing process)

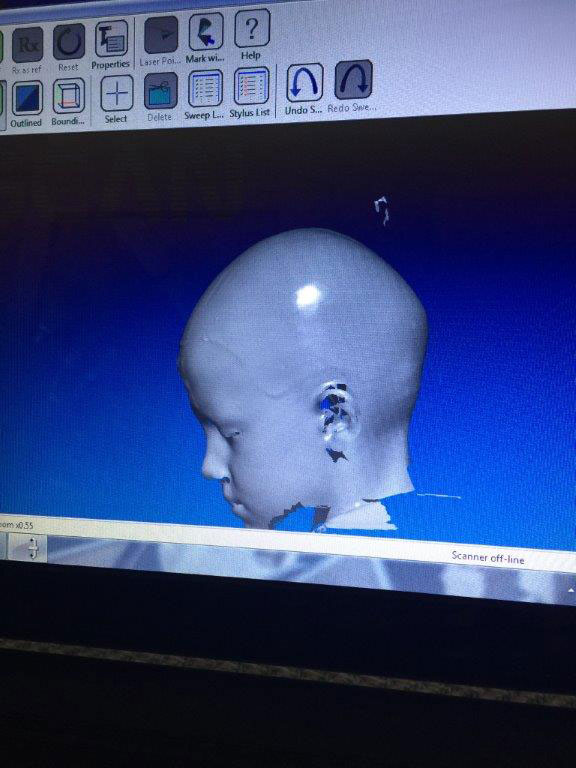

Your Freedom experience starts with a 3D medical scan. Our proprietry technology is designed exclusively to ensure a perfect fit. Your new hair is totally customised not one size fits most. Each person’s head is as individual as a fingerprint. Your scan becomes the digital blueprint for your custom hair prosthesis.

An example of a 3D medical scan by Freedom Wigs.

A mould is made:

An exact replica of your head is created and kept on file forever. We use this to start to build the skin of your new hair. Children usually need to be rescanned and a new mould created every 2 years.

A wooden mould from the above scan by Freedom Wigs.

Checking your fit:

A plastic fitting cap is created for you to double check your fit and feel.

Our team of hair prep ladies work tirelessly to sort and grade virgin ponytails into length, colour and curl preference. You will be sent a sample of your specific order before we start to implant.

Making your new skin:

Once approved the base of your new hair is hand made using a silicone skin material that is soft, thin and formed fitted to your head. The resulting base creates a suction that allows you to maintain a normal lifestyle, swim, play sports, there are no limits.

Implanting your new hair:

Our specialised manufacturing technique implants each hair one at a time, creating a lifelike scalp and even spread of hair. This ensures a natural appearance, natural feel and most importantly replicates the natural movement of a growing head of hair.

It takes years of experience to learn to implant our hair one at a time, in a natural growth pattern and varied density.

Our team if implanting technicians feel passionate doing this knowing they are helping to change the life of the person they are creating for.